|

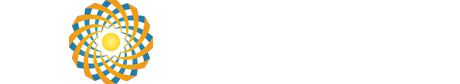

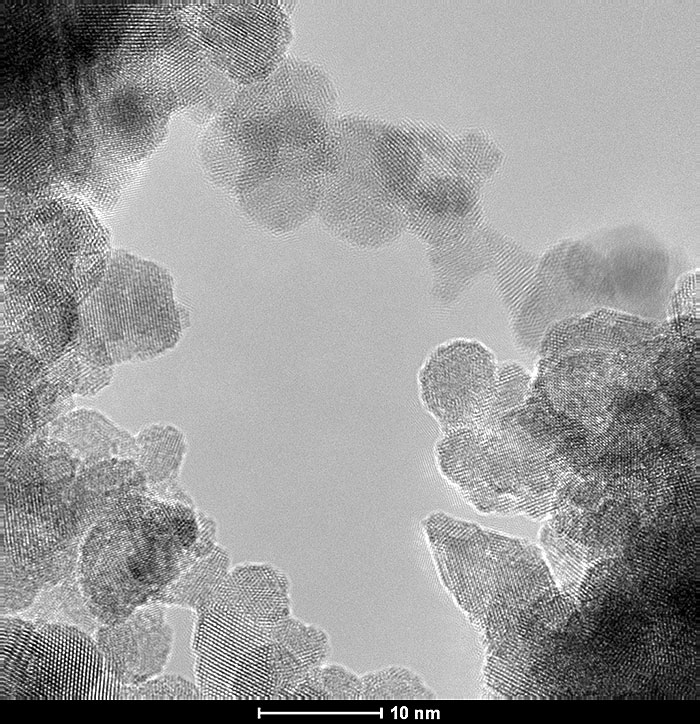

Zirconia (ZrO2) is an important material for many applications, due to its high hardness, high melting point, and biocompatibility. It exists in monoclinic phase, stable up to 1170°C, tetragonal phase stable up to 2370°C and cubic phase, stable up to 2715°C. Especially important for applications is the metastable, tetragonal phase, since its properties are more isotropic than for the monoclinic phase. Stress-induced tetragonal to monoclinic transformation of ZrO2 takes place in ZrO2- ceramics, which can block the crack propagation and prevent fracture. In such a case, if a crack grows through the ceramic, the zirconia particles in the region of the crack change from tetragonal (t) to monoclinic (m) phase with a martensitic transformation which is accompanied by a volume expansion of about 3%. This generates compressive stresses in the alumina matrix thus contrasting the opening of the advancing crack giving rise to increased toughness. In order to stabilize the tetragonal phase at room temperature, various stabilizers are used. The most common of them is Yttria (Yttrium oxide-Y2O3). Aluminina (Al2O3) as a stabilizer of the tetragonal phase is much less expensive than the conventionally used Yttria or other rare earth ions. |

Project title: The role of the grain size control on formation of phases in the zirconia-alumina (ZrO2-Al2O3) system

Number: UMO-2013/11/D/ST8/03429

National Science Centre, Sonata 6

Duration: 2014-2018

Project partner: Ben-Gurion University of the Negev, Beer Sheva, 8410501, Israel

Goal of the project:

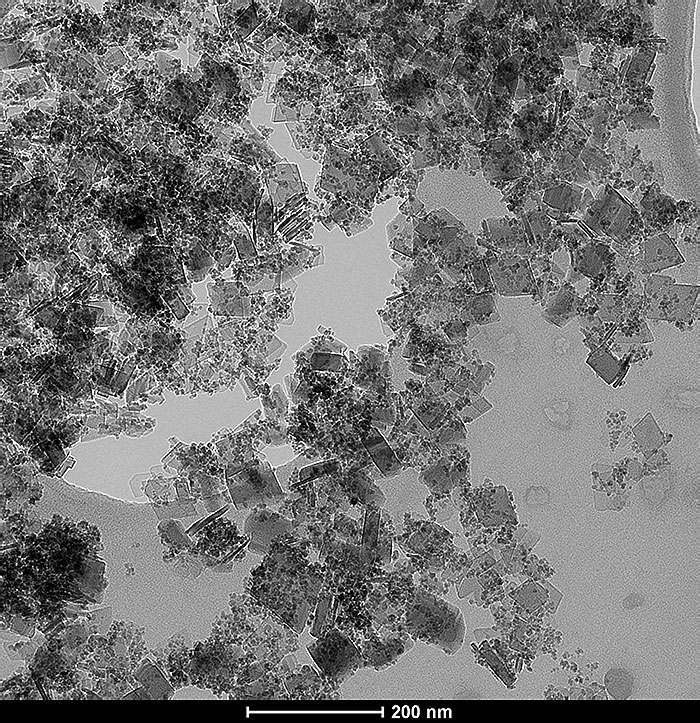

The main objective of the project is to develop a new class of zirconia-based solid solution materials (ZrO2 with Al3+) in a wide range of compositions. We will investigate whether the nanotechnology route, where formation of solid solution takes place during synthesis of nanoparticles influences low mutual solubility ZrO2-Al2O3 at temperatures lower than 1130°C. Mastering the technology of alumina-zirconia nanomaterials will be possible, once we will know:

- The composition range in which the solid solution exists;

- How ZrO2-Al2O3 crystallographic structure depends on its composition?

- How ZrO2-Al2O3 nanopowders thermal stability depends on grain size?

Thus a grain size dependent 3-D phase diagram needs to be developed.

Publications:

- Iwona E. Koltsov, M. Prześniak-Welenc, J. Wojnarowicz, A. Rogowska, J. Mizeracki, M. Malysa, G. Kimmel; Thermal and physical properties of ZrO2 ̶ AlO(OH) nanopowders synthesised by microwave hydrothermal method, Journal of Thermal Analysis and Calorimetry Nov, 2017, 10.1007/s10973-017-6780-8

- Iwona E. Malka, Anna Danelska, Giora Kimmel, The Influence of Al2O3 Content on ZrO2-Al2O3Nanocomposite Formation - The Comparison between Sol-Gel and Microwave Hydrothermal Methods, Materials Today: Proceedings, 10.1016/j.matpr.2016.06.018, 3 (2016) 2713–2724

Presentations:

- 2015

- ANM2015

20-22 July Aveiro, Portugal - 6th International Conference on Advanced Nanomaterials,

“The Influence of Al2O3 Content on ZrO2-Al2O3 Nanocomposite Formation” (oral presentation), Iwona E. Koltsov - PTCer2015

17-20 September 2015, Zakopane, Poland - ,10th Conference of The Polish Ceramic Society

“Zirconia-alumina nanopowders synthesized via hydrothermal microwave-assisted process and precipitation method” (oral presentation), A. Danelska - 2017

- EuroNanoForum 2017

21-23 June 2017, Malta, Valletta,

“Nanostructure and properties of ZrO2-Al2O3 solid solution obtained by microwave hydrothermal method (MHS)” (poster), I.Koltsov, J. Smalc-Koziorowska, M.Małysa, G. Kimel, W. Łojkowski, - NanoTechFrance2017

28-30 June 2017, Paris, International Conference and Exhibition“The effect of Al2O3 addition on ZrO2-Al2O3 nanoceramics formation and their properties” (poster) I. Koltsov, M. Małysa, J. Wojnarowicz, A. Rogowska, G. Kimmel, W. Łojkowski, - ChinaNano2017

29-31 August 2017, Beijing, China

“Al2O3–ZrO2 nanocomposites derived by microwave hydrothermal synthesis. Properties and applications" (oral presentation), Iwona Koltsov - 45 Szkoła Inżynierii Materiałowej,

26-29 September 2017Rytro, Poland

„Struktura spieków otrzymanych z nanoproszków ZrO2 - Al2O3 wytworzonych za pomocą mikrofalowej syntezy hydrotermalnej” (oral presentation), Maria Małysa