LABNANO RESEARCH ON SYNTHESIS AND APPLICATIONS OF NANOPARTICLES

The present research focusses on ideas developed in the years 2005- 2009, during interactions supported by the European COST action D32, “Chemistry in High Energy Microenvironments”. COST – European Cooperation in Science and Technology supports interdisciplinary networking. Action D32 explored application of microwaves, high pressures and ultrasounds in synthesis of nanoparticles: https://www.cost.eu/publication/chemistry-in-high-energy-microenvironments/.

The present research focusses on ideas developed in the years 2005- 2009, during interactions supported by the European COST action D32, “Chemistry in High Energy Microenvironments”. COST – European Cooperation in Science and Technology supports interdisciplinary networking. Action D32 explored application of microwaves, high pressures and ultrasounds in synthesis of nanoparticles: https://www.cost.eu/publication/chemistry-in-high-energy-microenvironments/.

Nanoparticles are particles of materials with size smaller than 100 nm. Experiments have shown that approximately at this dimension many properties of materials start to be a function of their particles size. The size dependence of nanomaterials properties opened a new universe of research in hope of discovering new phenomena, new properties, and new applications. To do so it is necessary to precisely control the size of the nanoparticles, control their chemical composition, and crystalline structure.

Traditional chemical methods frequently fail to achieve the above goals. There is a very strong thermodynamic driving force to increase the particles size. It is like coalescence of small soap bubbles to form larger ones. To prevent this to occur, chemists tend to shorten the reaction time or decrease the reaction temperature. However, a negative side effect is that the obtained nanoparticles are not fully crystalline. Collaboration of experts in high pressure and microwave technologies within the COST D32 Action has led to successful synthesis of nanoparticles using the so-called Microwave Hydrothermal Synthesis or Microwave Solvothermal Synthesis – MSS.

In the hydrothermal or solvothermal process, the substrates of the reaction are enclosed in a high-pressure vessel and heated above the boiling temperature for the atmospheric pressure. Heating is carried out until the reaction start. A high temperature is achieved, and the degree of nanoparticles crystallinity is high. The temperature is significantly lower than during the known sol-gel followed by calcination processes.

However, it is impossible to quickly heat substrates enclosed in a high-pressure vessel. A traditional heater would quickly heat one part of the liquids, while the other part would be cold and the particle’s size distribution would be broad. Heating the whole vessel is slow and reaction time control very difficult. The solution which we use is to heat the reactants enclosed in the high-pressure vessel using microwaves: the MSS process.

To achieve an efficient MSS process it was necessary to develop methods to supply microwave energy into the pressure vessel, and to control such a process. It was also important to achieve a high microwave energy density in the vessel, like 1 W/ml, so that heating is fast, as well as reproducible, and the reaction yield is significant. Since 2009 we developed subsequently improved reactors: MSS1, MSS2, MSS3 and MSS4. Both MSS2 and MSS4 (Fig.1) are beyond the state of the art, as far as microwave energy density, control, automation, and yield. The reactors permit to heat a volume of 200 – 350 ml at a speed of 1 to 2 K/s and control the reaction time with time resolution of a few seconds. Heating times of 90 sec are possible. The achievable pressure is 6 MPa and temperature 260oC.

Figure 1. The MSS4 reactor. Automatic loading of the reaction chamber.

Schematic comparison of the temperature inside the vessel as function of time for microwave and conventional heating.

Computer modelling shows that the temperature inside of the vessel increases uniformly.

The temperature gradients at 250oC are less than 5oC for heating rate 1 K/sec.

We applied the MSS technology to obtain nanoparticles of: Fe2O3, ZnO, ZnO doped with Co and Mn ions, ZnO mixed with nanoAg and nanoCu, ZrO2 doped with a wide range of rare earth ions, TiO, and nano-Hydroxyapatite HAP. We were able to control the degree of crystallinity and size. We developed strongly antibacterial materials, novel nanomaterials for dactyloscopy in criminalistics, as well as a nanomaterial for oxygen partial pressure determination. The technologies are ready for commercialization. However, most advanced in practical applications tests is nano-sized HAP – Hydroxyapatite.

Hydroxyapatite is the only ceramic material in our bodies. It is found both in nature, and in our bones. However, in our bones it takes the form of nanoparticles, platelets a few nanometres thick and about 10 nm long. Their exact shape depends on the part of the bone they are situated. The nano-hydroxyapatite we produce using the MSS reactors is very similar in structure to the natural one. Figure 2 shows a leaflet advertising our patented nanomaterial, which we registered in the patent office as GoHAP™. Precise control of reaction time and pressure in the MSS reactor permits to offer a range of 6 GoHAP™ nanoparticles, differing in nano-crystal size.

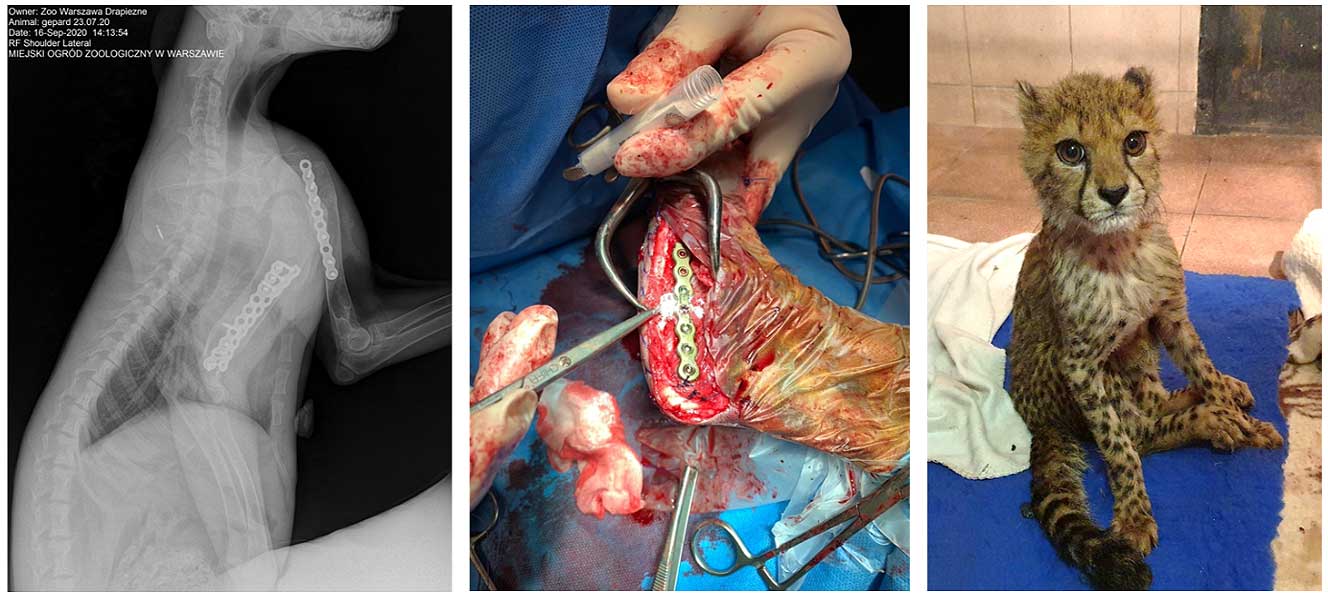

GoHAP™ in form of powders or pastes can be applied to accelerate bone regrowth in patients suffering after complicated bone fractures or when large gaps are created in the bone tissue after removing bone cancer. The demand for such materials is huge. Several materials are on the market, but we are aware of only three companies exploring the advantages of nanostructure of the materials. None of them offers a material with structure like that of natural bone. Due to its nano-size, and low temperature of synthesis GoHAP™ dissolves in water and is therefore biodegradable. In several papers we have shown its positive effect on osteogenic cells spreading and growth as well as bone growth stimulating functions. Biocompatibility tests requested for active implants are under way, and the preliminary results are positive. Until these tests are accomplished, the material is used in veterinary orthopaedics. Figures 3,4,5 show examples of practical applications of GoHAP in veterinary.

In summary:

- Nano-hydroxyapatite GoHAP™ is a nanomaterial stimulating bone regrowth with precisely tuned particle size and a structure nearly identical to the natural material from which bones are built. At present it is used as a paste obtained by mixing it with blood.

- A technology for ultrasonic coating of biodegradable membranes GoMEM with GoHAP™ has been developed (Fig.6).

- A certificate confirming the production of GoHAP™ and GoMEM membranes in accordance with the ISO 13485 standard required for medical implants has been obtained. To our knowledge, only 3 companies in the world have such certification for nano-size HAP, but unlike GoHAP, the material they produce is not nano-sized in a way identical to the natural one.

- A contract with a company has been signed for coating with GoHAP™ of titanium implants used in spinal-cord diseases in clinical medicine. Funding is searched for clinical tests.

- A contract has been signed with Intergoss Ltd. for development of a paste containing GoHAP™ for filling with it into 3D titanium implants used in spinal-cord diseases.

- An international patent was obtained on using of microwave technology to uniformly coat a wide range of 3D materials, like 3D printed implants, fibrous materials, polymers, ceramics, metals, with a uniform layer of GoHAP™ and improve their bone stimulation properties.

- A patent was obtained for making robust biodegradable composites with a high GoHAP™ content.

- Further work is in progress to:

- Improve the methods of application of GoHAP™ in real trauma or cancer cases.

- Develop materials combining bone growth stimulation and mechanical strength.

- Control the biodegradation rate by mixing nanoparticles of various sizes.

- Combine antibacterial, angiogenesis, and bone generation functions.

- Understand basic mechanism of their biological effects

- Test new fields of medical applications.

- GoHAP is used in everyday practice during orthopaedic surgery in two renowned veterinary clinics. Over 100 treatments were performed to treat bone fractures in horses, dogs, and Cheetahs from the Warsaw Zoo. There was a significant acceleration of the process of growth, or fusion of bones in situations where this was not expected. Suffering of animals and their owners has been reduced.

- Basic research has shown that GoHAP™ interacts with Osteoblasts and Mesenchymal stem cells increasing their spreading and proliferation. In our opinion this is due to size dependent calcium ions signal generated by the nanoparticles.

Relevant active patents:

- “Method for manufacturing bone implants and bone implant” US 11,260,148 B2, EP 3291850 B1, PAT.226891

- "Biological barrier membrane" PAT.240082

- "A method for obtaining nanoplatelets from synthetic hydroxyapatite". PAT.235292

The CePT I and CePT II infrastructure projects, co-funded by the European Union, permitted to create a space for synthesis of GoHAP™ as well as coated with GoHAP™ biodegradable membranes for tissue separation at a scale that permits experimental production – an intermediate step before commercialization of the technology.

In 2023 an application will be filled to the certification agency to obtain the CE certificate allowing application of GoHAP™ in clinics. Further, funding for clinical tests will be sought for clinical applications of sonocoating with GoHAP™ and for clinical applications of GoMEM membranes.

The above achievements were possible because of the initial impulse given by the COST D32 action, to combine microwave technology, high pressure technology, ultrasonic technology, and chemical synthesis knowledge to produce nanoparticles of narrow grain size distribution, controllable size, and high degree of crystallinity. The key factors are short time, fast uniform heating, moderate temperature of synthesis, and high purity. Further, significant funding by national and European research funding agencies, and especially by infrastructure projects CePT I and CePT II.

Figure 2: Leaflet with GoHAP™ offer.

Figure. 3. Surgery of a broken paw in a cheetah from the Warsaw Zoo.

Brave patient, powder dosing during surgery and X-ray control after surgery.

Surgery performed at Pulaski 24 Clinic.

Source: Dr. n. wet. Igor Bissenik, Ph.D., and Dr Agnieszka Czujkowska - Municipal Zoological Garden in Warsaw.

Figure 4. Surgery to support the overgrowing of bone loss for the jaw of a horse with broken teeth.

The hole was covered with GoHAP powder, which caused the bone hole to grow rapidly.

Surgery performed in the "Szpotański" Horse Clinic.

Figure 5. World’s first operation of broken splint bone in a horse using an electro-spun membrane

coated with nanohydroxyapatite. The membrane was produced in the Laboratory of

Nanostructures and coated ultrasonically with GoHAP™.

Selected publications

- Highly biocompatible, nanocrystalline hydroxyapatite synthesized in a solvothermal process driven by high energy density microwave radiation, D Smolen, T Chudoba, I Malka, A Kedzierska, W Lojkowski, ...International journal of nanomedicine 8, 653, 2013

- Comprehensive structural studies of ultra-fine nanocrystalline calcium hydroxyapatite using MAS NMR and FT-IR spectroscopic methods, L Pajchel, V Kowalska, D Smolen, A Kedzierska, E Pietrzykowska, ...W Lojkowski, Materials Research Bulletin 48, 4818-4825, 2013

- Influence of hydrothermal synthesis parameters on the properties of hydroxyapatite nanoparticles, S Kuśnieruk, J Wojnarowicz, A Chodara, T Chudoba, S Gierlotka, ... W Łojkowski, Beilstein journal of nanotechnology 7, 1586-1601, 2016

- Polymer membranes sonocoated and electrosprayed with nano-hydroxyapatite for periodontal tissues regeneration, J Higuchi, G Fortunato, B Woźniak, A Chodara, S Domaschke, ... W Łojkowski, Nanomaterials 9, 1625, 2019

- In vivo and in vitro study of a novel nanohydroxyapatite sonocoated scaffolds for enhanced bone regeneration, J Rogowska-Tylman, J Locs, I Salma, B Woźniak, M Pilmane, V Zalite, ... W Łojkowski, Materials Science and Engineering: C 99, 669-684, 2019

- Drug-Releasing Antibacterial Coating Made from Nano-Hydroxyapatite Using the Sonocoating Method, K AbouAitah, M Bil, E Pietrzykowska, U Szałaj, D Fudala, B Woźniak, ...W Lojkowski, Nanomaterials 11, 1690, 2021

- Biodegradable ceramic matrix composites made from nanocrystalline hydroxyapatite and silk fibers via crymilling and uniaxial pressing, E Pietrzykowska, M Małysa, A Chodara, B Romelczyk-Baishya, K Szlązak, ...W Lojkowski, Materials Letters 293, 129672, 2021

- Osteogenic Potential of Sheep Mesenchymal Stem Cells Preconditioned with BMP-2 and FGF-2 and Seeded on an nHAP-Coated PCL/HAP/β-TCP Scaffold, S Stamnitz, A Krawczenko, U Szałaj, Ż Górecka, A Antończyk, Z Kiełbowicz, W Święszkowski, W Łojkowski, A Klimczak, Cells, 11, 3446, 2022

- Microstructure and mechanical properties of inverse nanocomposite made from polylactide and hydroxyapatite nanoparticles, E Pietrzykowska, B Romelczyk-Baishya, A Chodara, I Koltsov, H Smogór, ...W Lojkowski, Materials 15, 184, 2022

Figure 6. Leaflet with sonocoating service offer